About Us

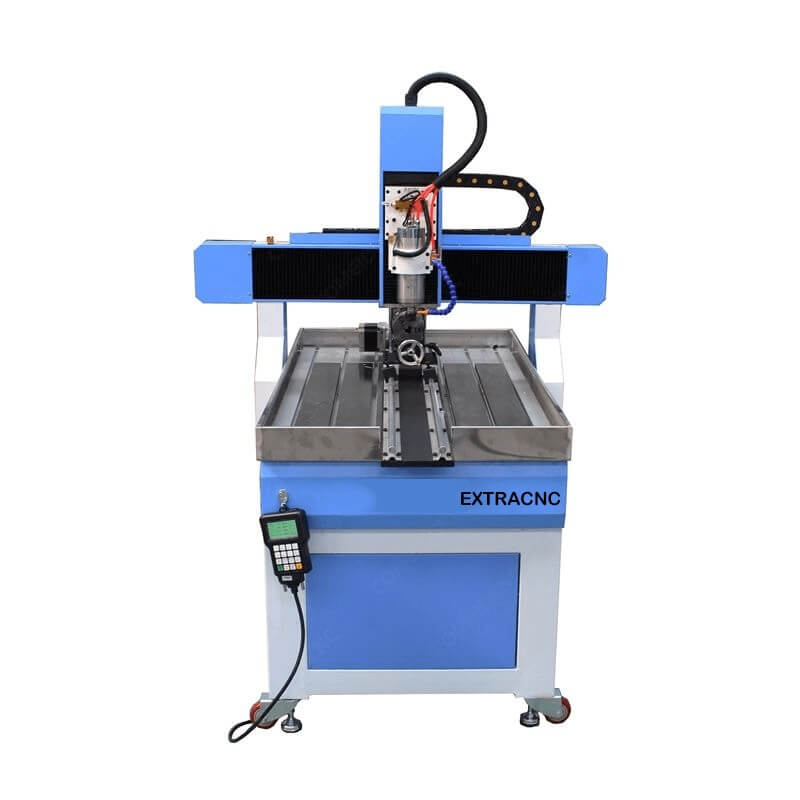

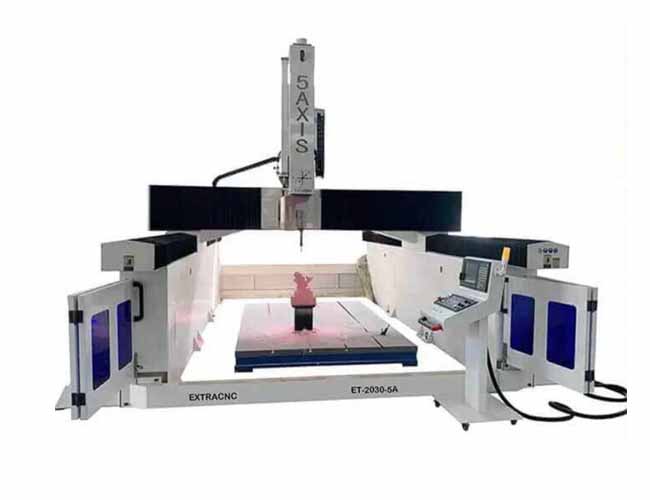

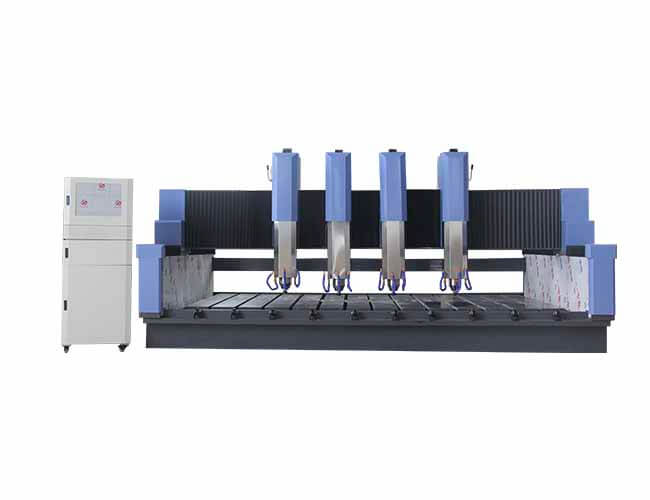

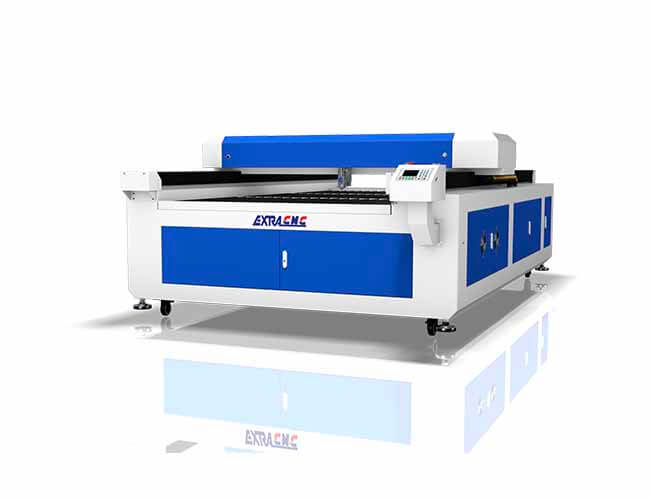

Jinan EXTRA CNC Equipment Co., Ltd. (EXTRA CNC) is a high-tech enterprise specializing in the research, development, production, and sales of CNC machinery. We are committed to delivering high-quality, high-efficiency CNC solutions to customers worldwide. Our product range includes CNC routers, laser cutting machines, plasma cutters, woodworking lathes, oscillating knife cutters, and more—widely used in woodworking, advertising, metal fabrication, mold making, stone carving, foam modeling, and other industries.

As a professional CNC machine manufacturer, EXTRA CNC is equipped with an experienced technical team and modern production facilities. We offer customized machine solutions to meet diverse material processing needs. Guided by the principle of “Quality First, Customer Focused,” we strive for excellence in every step—from machine design and manufacturing to after-sales service.

Over the years, our machines have been exported to Europe, North America, Southeast Asia, the Middle East, South America, and other regions. Our growing global customer base is a true testament to the reliability of our products—Customers’ Numbers Speak for our reputation and strength.

We warmly welcome partners from all over the world to join hands with us in shaping the future of CNC technology!