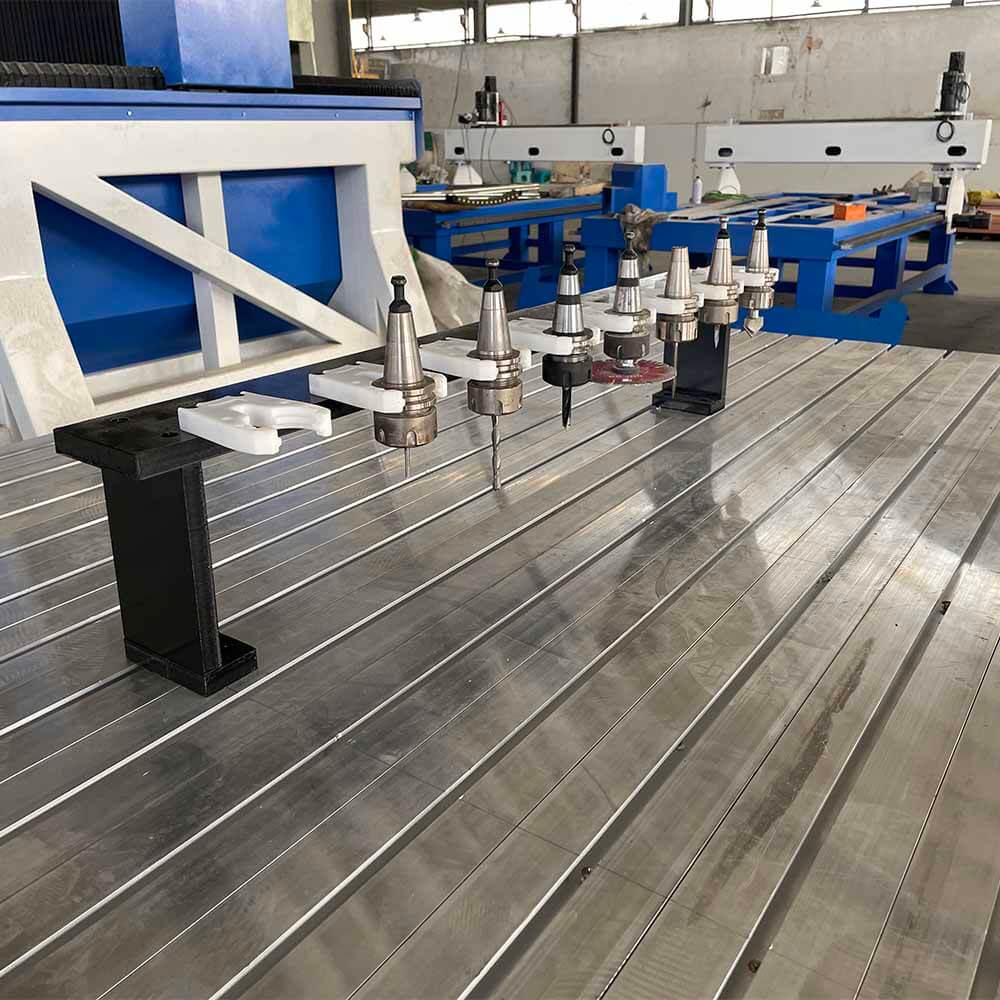

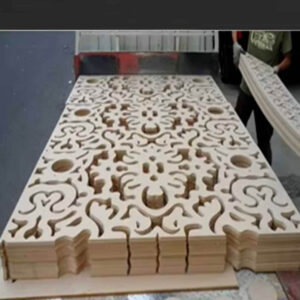

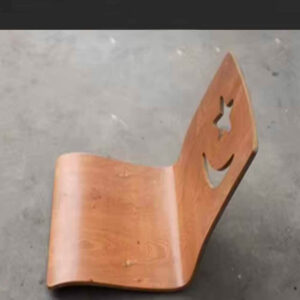

The 4-axis CNC router, also referred to as a 4-axis CNC machine, 4-axis router, or 4-axis machining center, features four coordinated axes: X, Y, Z, and A. This design allows the X, Y, Z, and A axes to operate simultaneously, enabling more complex machining tasks. Unlike a 3-axis CNC router, which operates only in linear directions, the 4-axis CNC router can process workpieces from multiple angles, allowing for machining on both sides of the material.