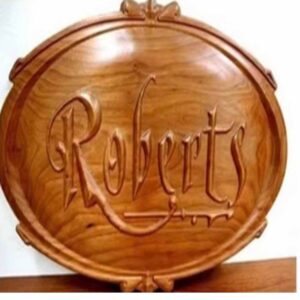

The 3D CNC Router is a versatile machine designed for cutting, milling, and engraving a wide variety of materials, including wood, EPS, foam, fiberglass, and composites. It is widely used in industries such as die and mold making, musical instrument manufacturing, advertising, and interior design. This machine is perfect for producing intricate molds, 3D sculptures, signage, and decorative architectural elements with high precision and efficiency.