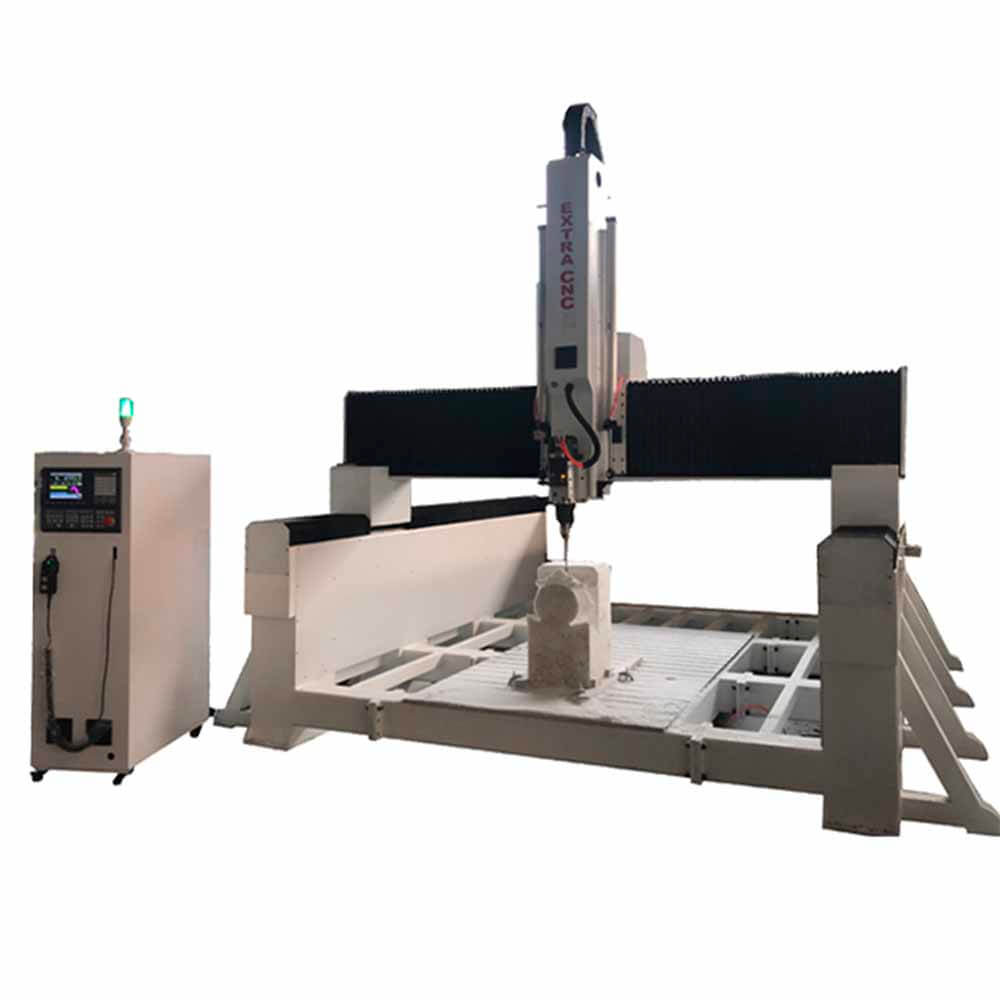

The 4-Axis CNC Foam Cutter is widely used across industries such as mold making, musical instrument manufacturing, and non-ferrous metal processing. It is ideal for creating intricate sculptures, large non-metallic molds, and custom models from materials like EPS foam, wood, MDF, acrylic, aluminum, and plastics. This versatile machine excels in producing complex shapes with high precision, making it perfect for applications in automotive, architecture, and design, as well as for crafting 3D prototypes and models in a wide range of industries.