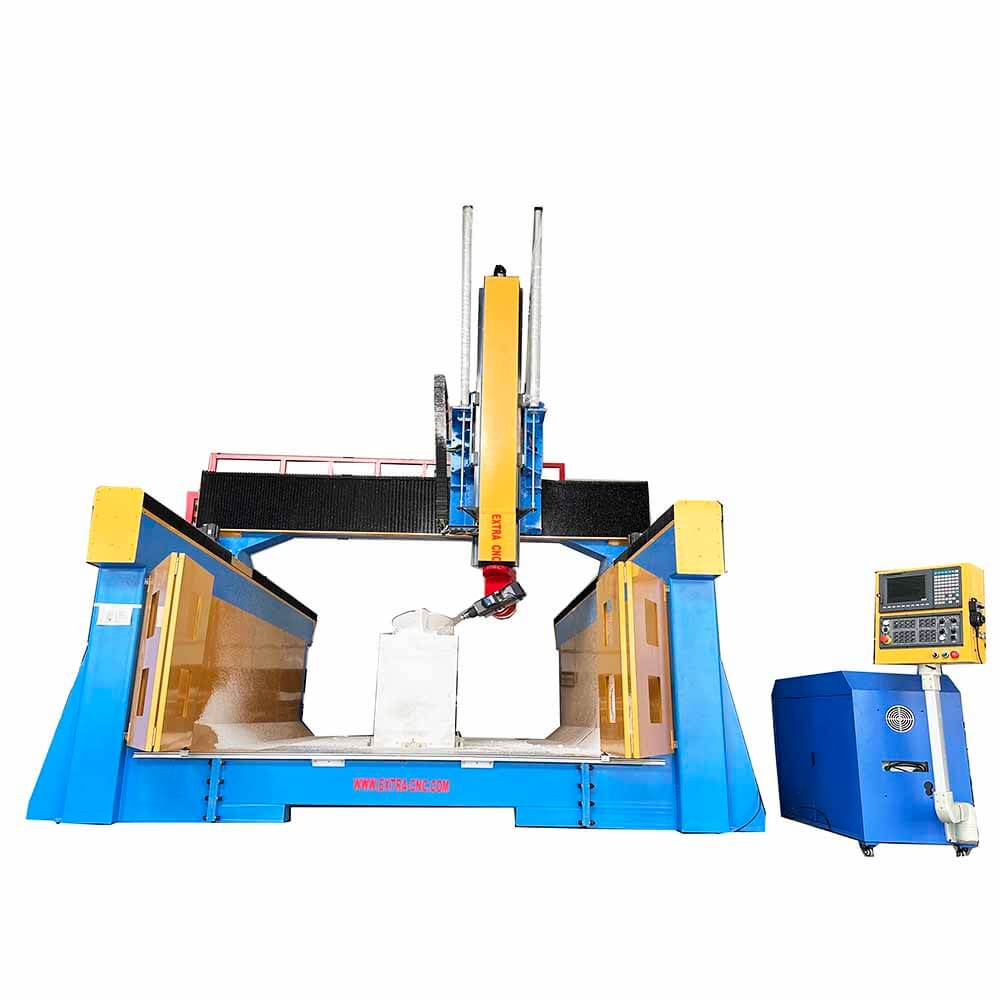

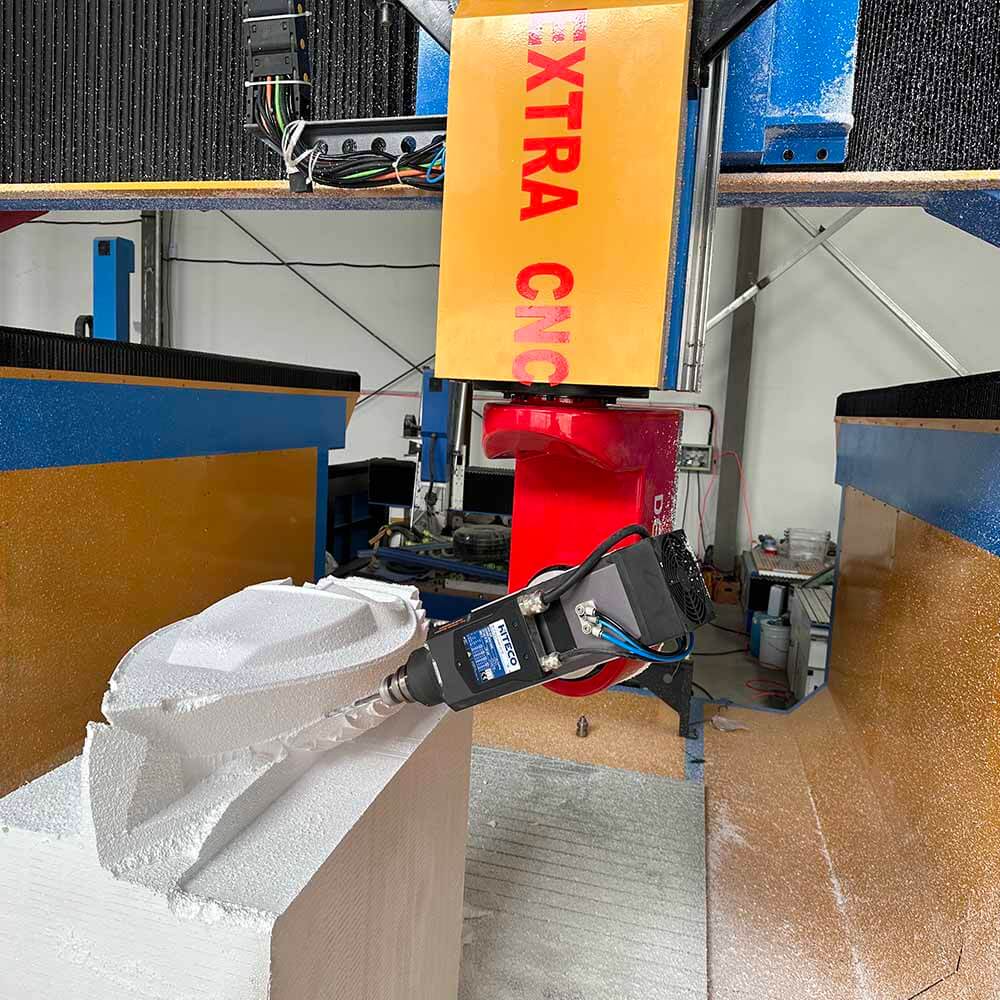

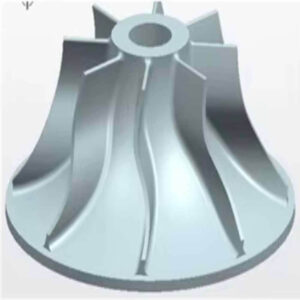

This 5-axis CNC mold machining center is designed for carving 3D molds from wood and EPS foam, as well as for machining sculptures, valve components, camshafts, plate discs, tank shells, and other non-metallic parts. It excels in milling, drilling, and boring operations, making it particularly suitable for creating intricate convex models, complex cavities, contoured surfaces, and detailed sculptures, meeting the demands of industries requiring high precision and versatility.