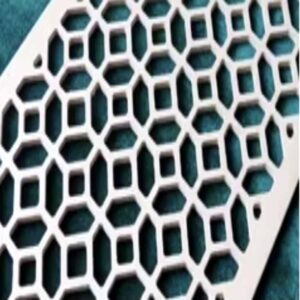

The ET1325ATC-D CNC Router is perfect for precision woodworking applications, including cabinet making, furniture production, and decorative pieces. It handles engraving, cutting, drilling, and milling with high accuracy, offering efficiency and automation for customized wood products.