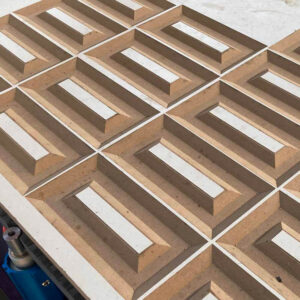

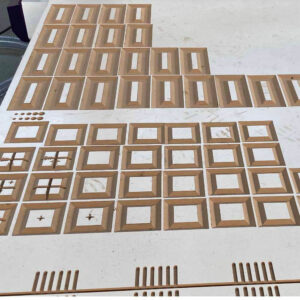

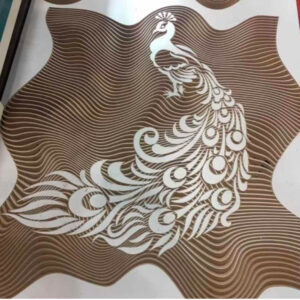

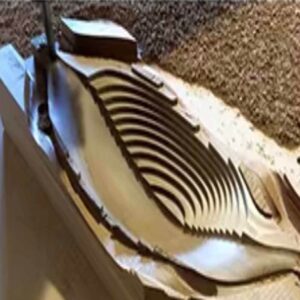

The ATC CNC Router with Drill Block, Tool Magazine, and Cut Saw is a versatile, high-precision woodworking machine ideal for a range of applications. Perfect for custom cabinetry, furniture manufacturing, architectural woodworking, and detailed decor, it streamlines complex processes like drilling, cutting, and grooving with speed and accuracy. From kitchen cabinets and doors to 3D wood carvings and retail displays, this router offers reliable, efficient production for both artistic and functional projects.