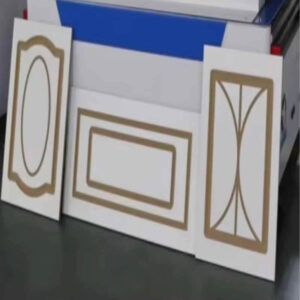

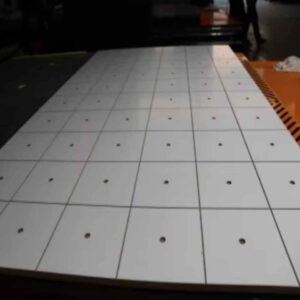

The Automatic 2030 CNC Router with Tool Changer is perfect for industries like furniture making, interior decoration, arts and crafts, and material processing. It automates tasks such as labeling, feeding, cutting, drilling, engraving, and discharging, improving efficiency and reducing labor for customized production.