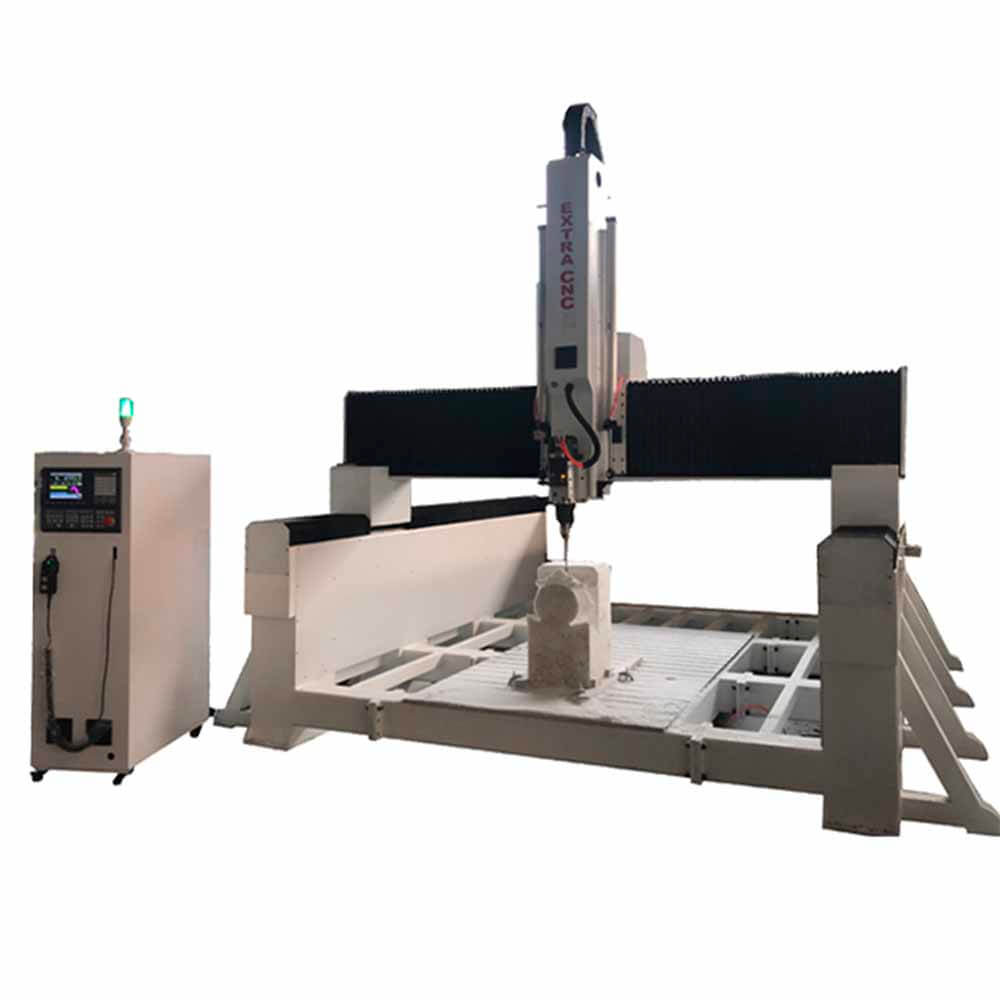

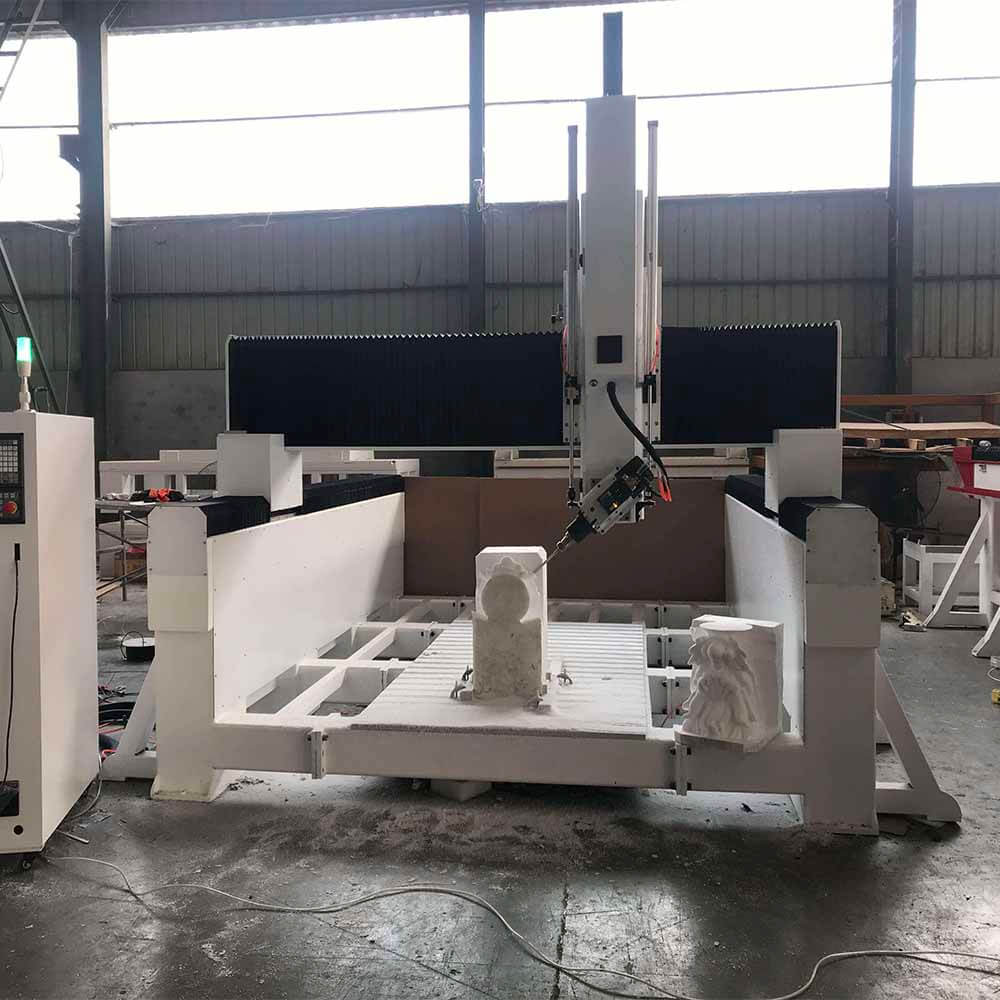

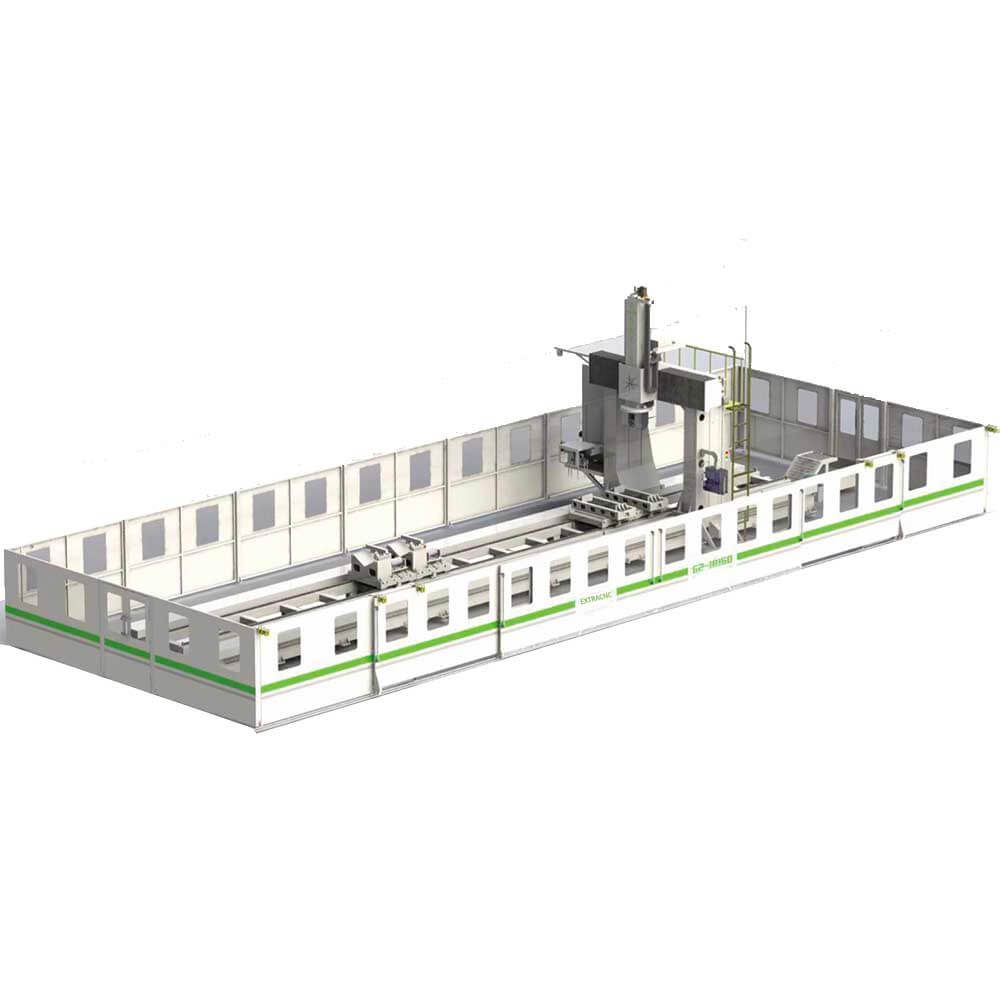

The 1825 ATC Foam Router is ideal for precision cutting and carving of EPS foam, XPS foam, and other foam materials. Its Automatic Tool Change (ATC) feature enhances efficiency by automatically switching tools during operation, making it perfect for industries like automotive, mold making, advertising, and prototyping. With a large working area and high-precision spindle, this machine is designed to create detailed 3D shapes, molds, and intricate patterns with ease.