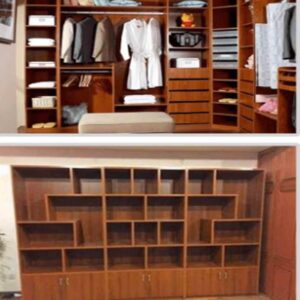

The 5×10 ATC CNC Router is ideal for the wood furniture industry, creating custom pieces like doors, screens, and furniture. In advertising, it handles sign making, acrylic engraving, and crystal lettering. It’s also perfect for die making, processing molds from metals, marble, PVC, and wood.