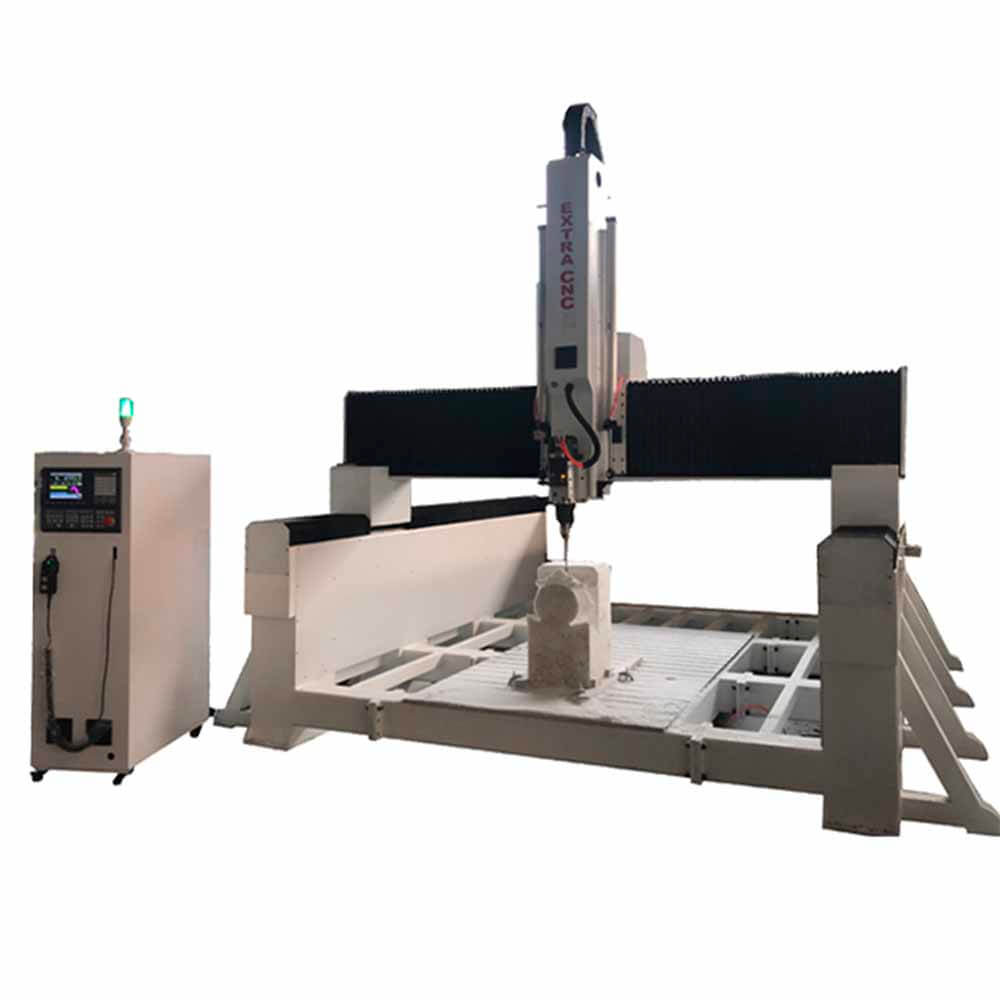

This 5-axis machining center is highly versatile, finding applications across numerous industries, including solid wood and large-scale furniture production, mold manufacturing, construction, machinery fabrication, automotive prototyping, precision instrument crafting, medical device production, musical instrument making, statues and sculptures, box-shaped components, and the creation of complex curved surfaces.