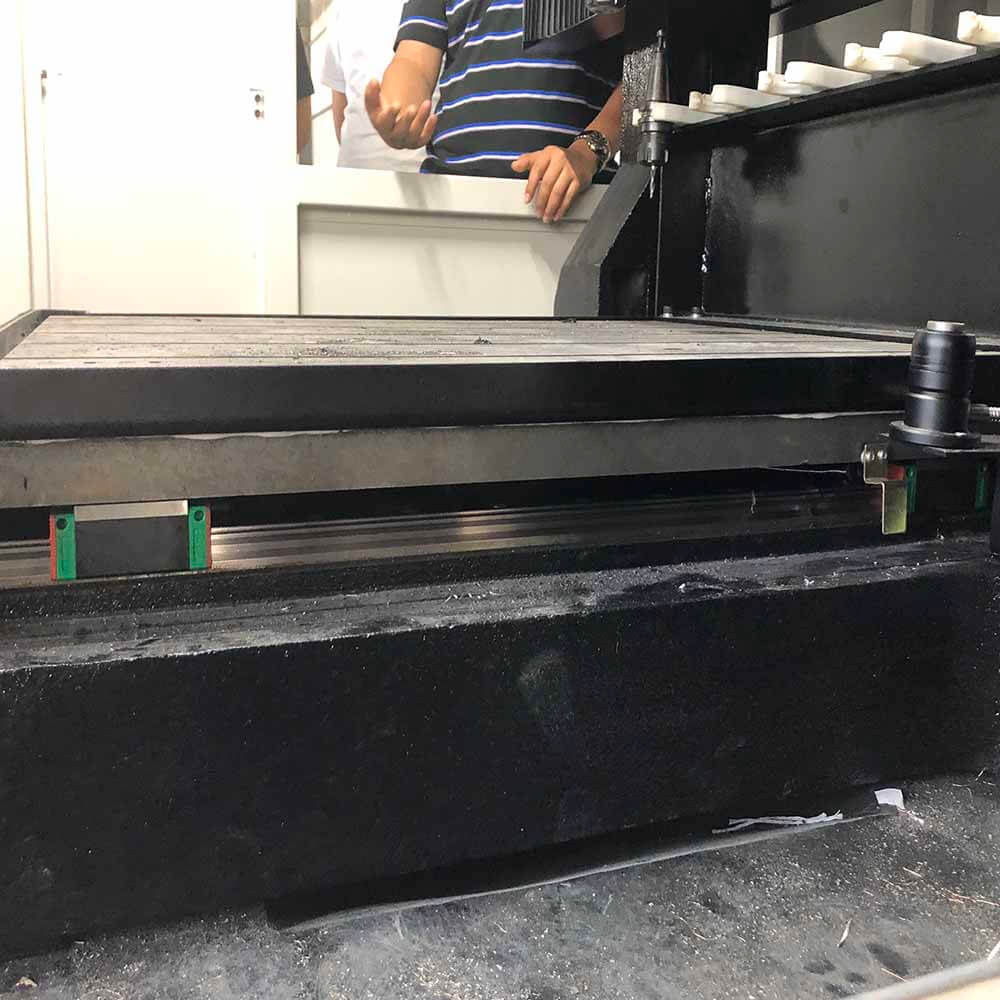

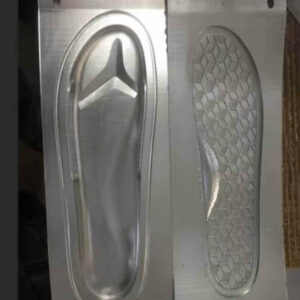

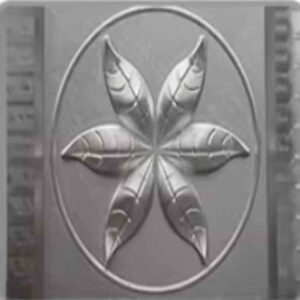

The hobby CNC mill is perfect for custom projects and small-scale manufacturing, capable of machining a variety of materials like metal, wood, and plastics. It’s ideal for mold making, prototype development, and creating custom parts for industries like automotive, jewelry, and signage. This versatile machine offers precision and efficiency for hobbyists and small businesses.