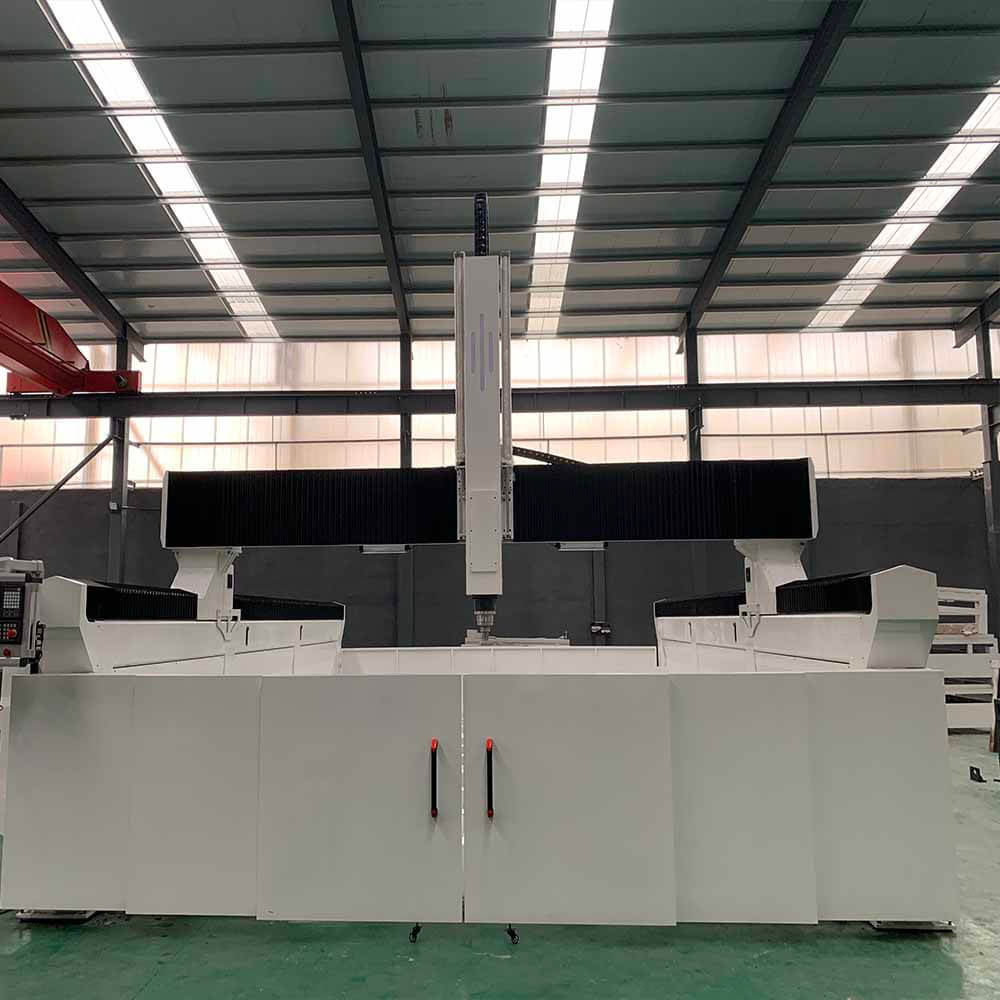

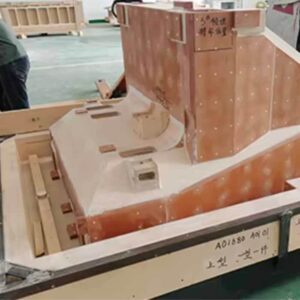

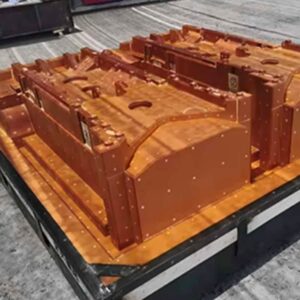

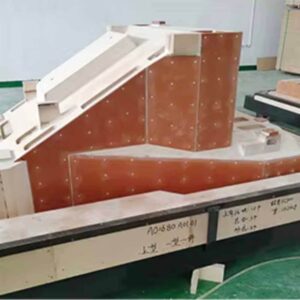

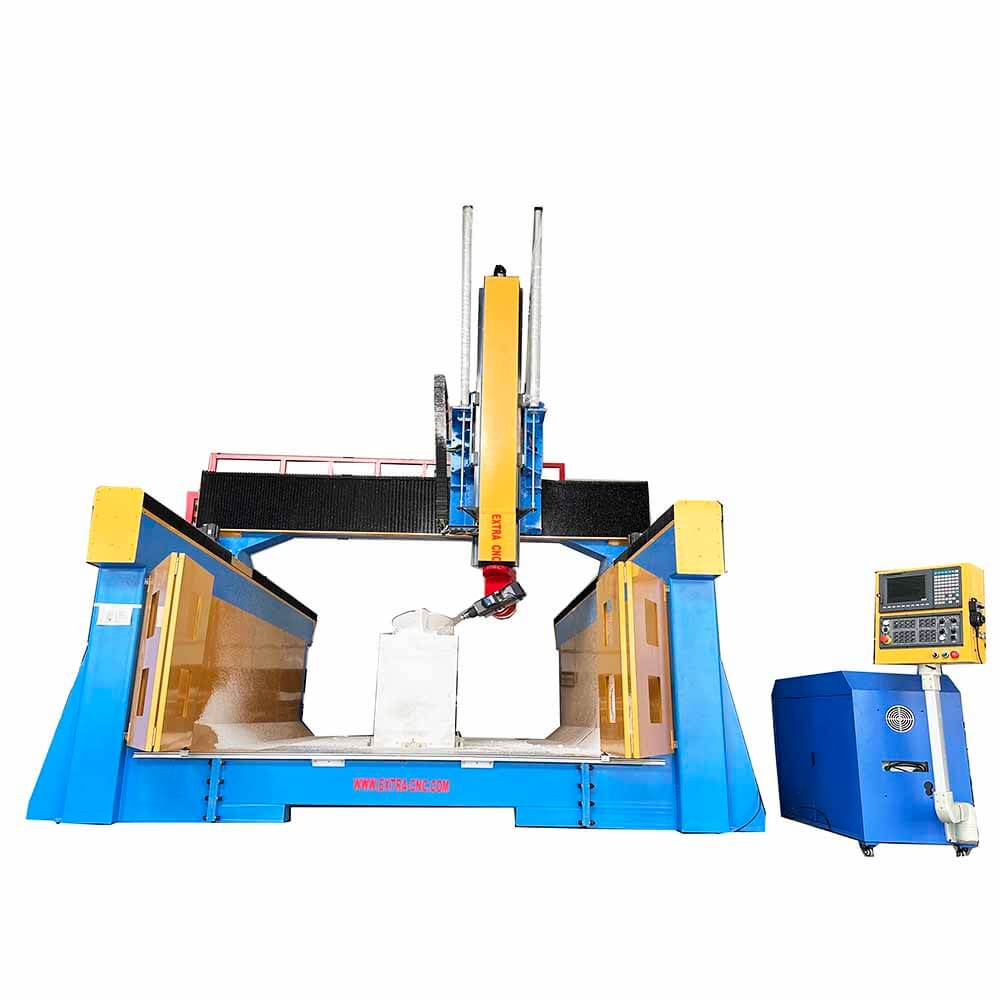

The Customized 2030 CNC Polystyrene Cutting Machine is perfect for a variety of industries. In furniture manufacturing, it creates intricate designs for wood, doors, and decorative pieces. In advertising, it excels at engraving and cutting acrylic signs and custom promotional materials. Additionally, it’s ideal for die and mold production, capable of working with metals and non-metallic materials like PVC, plastic, and wood to create custom molds and sculptures.