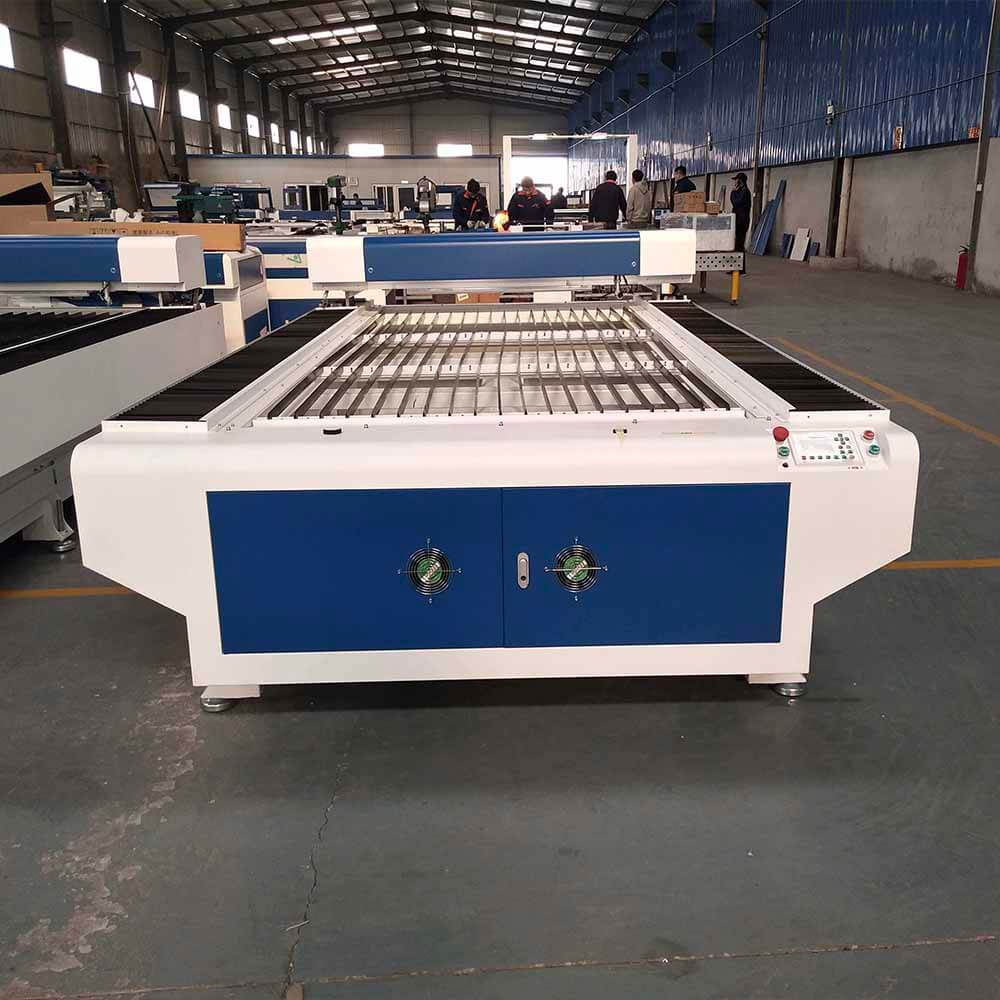

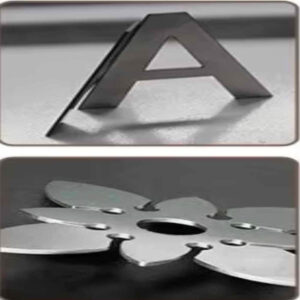

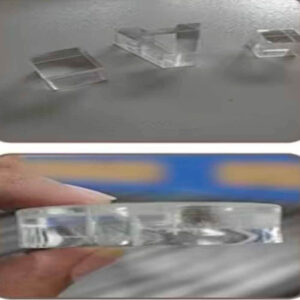

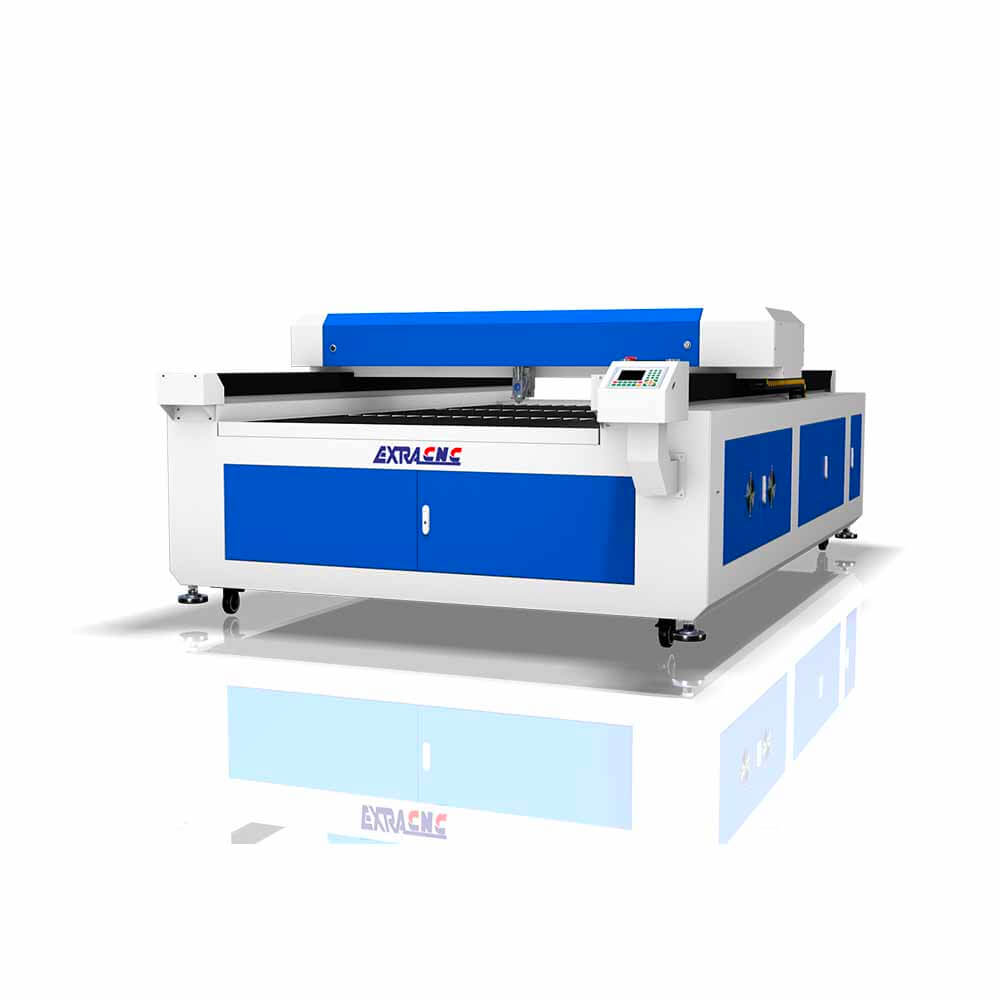

The Fiber & CO2 Combo Laser Cutting System is ideal for industries such as advertising, signage production, furniture manufacturing, and custom fabrication. It efficiently processes metal materials like stainless steel and aluminum, as well as non-metal materials such as acrylic, wood, and leather, making it perfect for cutting, engraving, and etching applications across a variety of sectors.