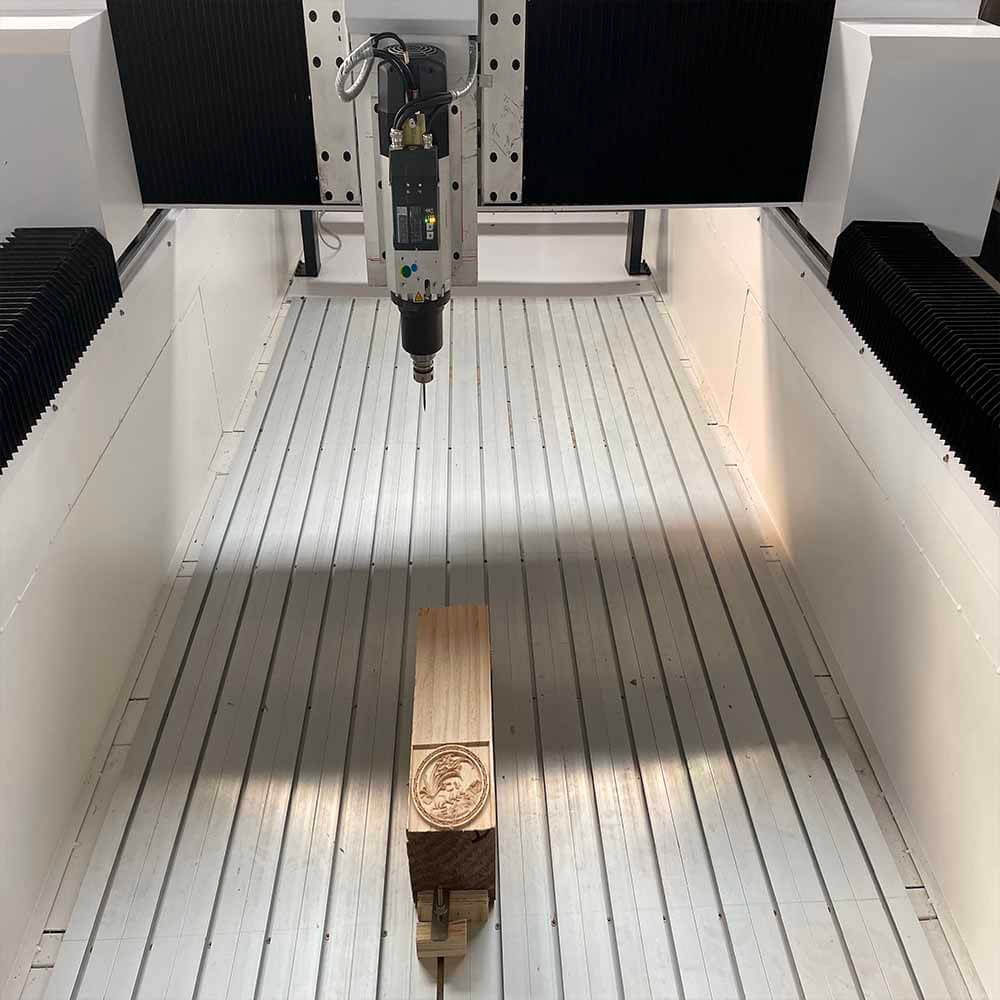

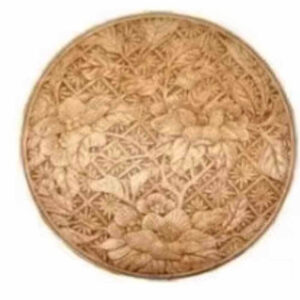

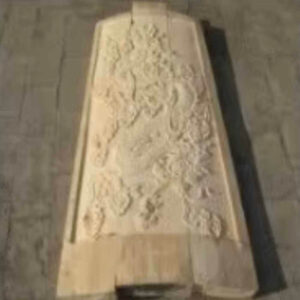

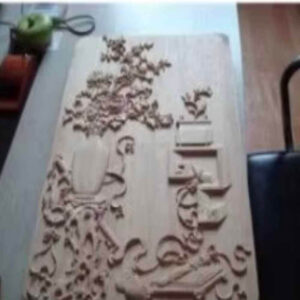

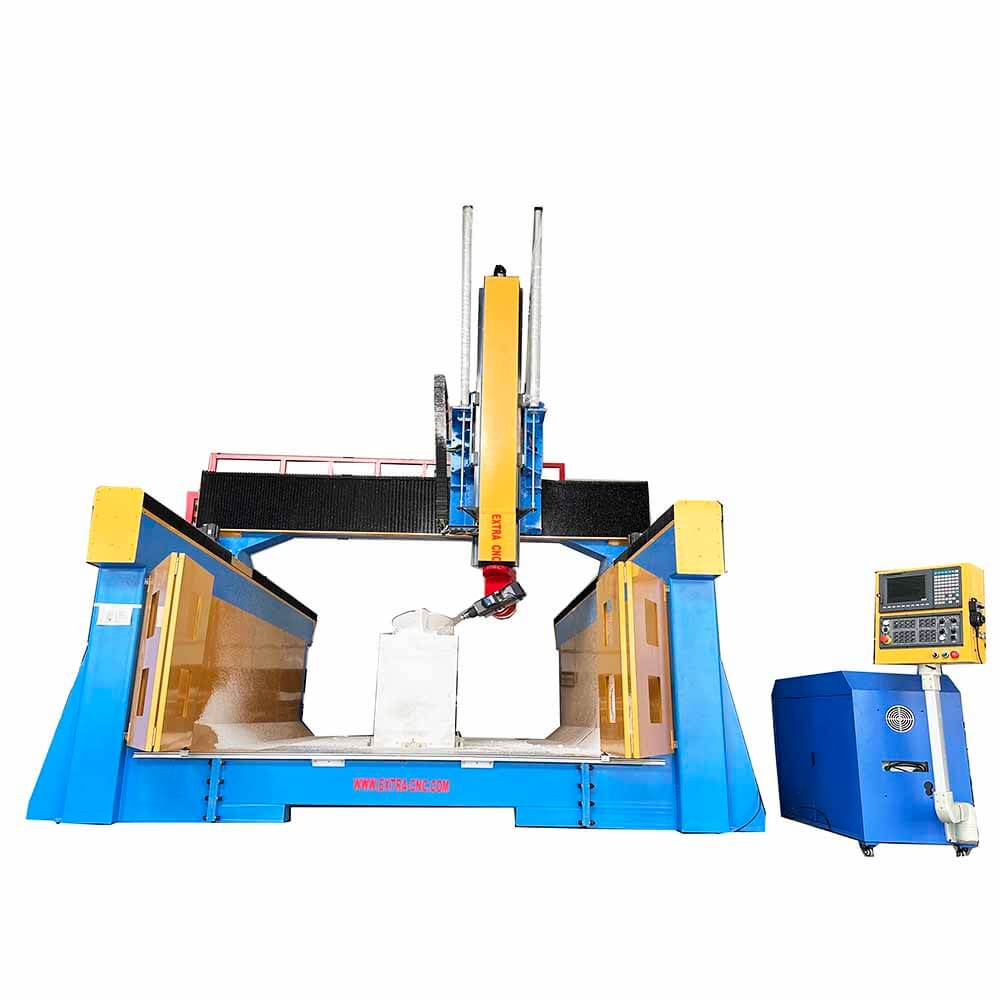

The CNC Router is widely used across various industries, including woodworking for crafting furniture, doors, and decorative elements; advertising for creating signs, acrylic engravings, and promotional displays; and the mold and die industry for producing molds from metals, plastics, and non-metallic materials. Its versatility makes it ideal for precise cutting and shaping in these sectors.