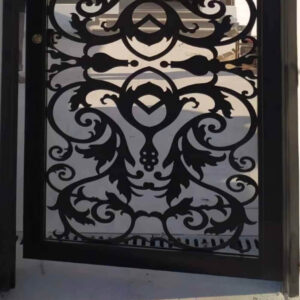

The CNC plasma cutting machine is perfect for cutting materials like steel, aluminum, and titanium with speeds up to 18m/min and precision of ±0.3mm. It provides clean, accurate cuts and can be integrated with other equipment in industries such as metal fabrication and automotive. The machine supports G-code and DXF files, offering high precision and easy operation with laser positioning and a user-friendly control system.