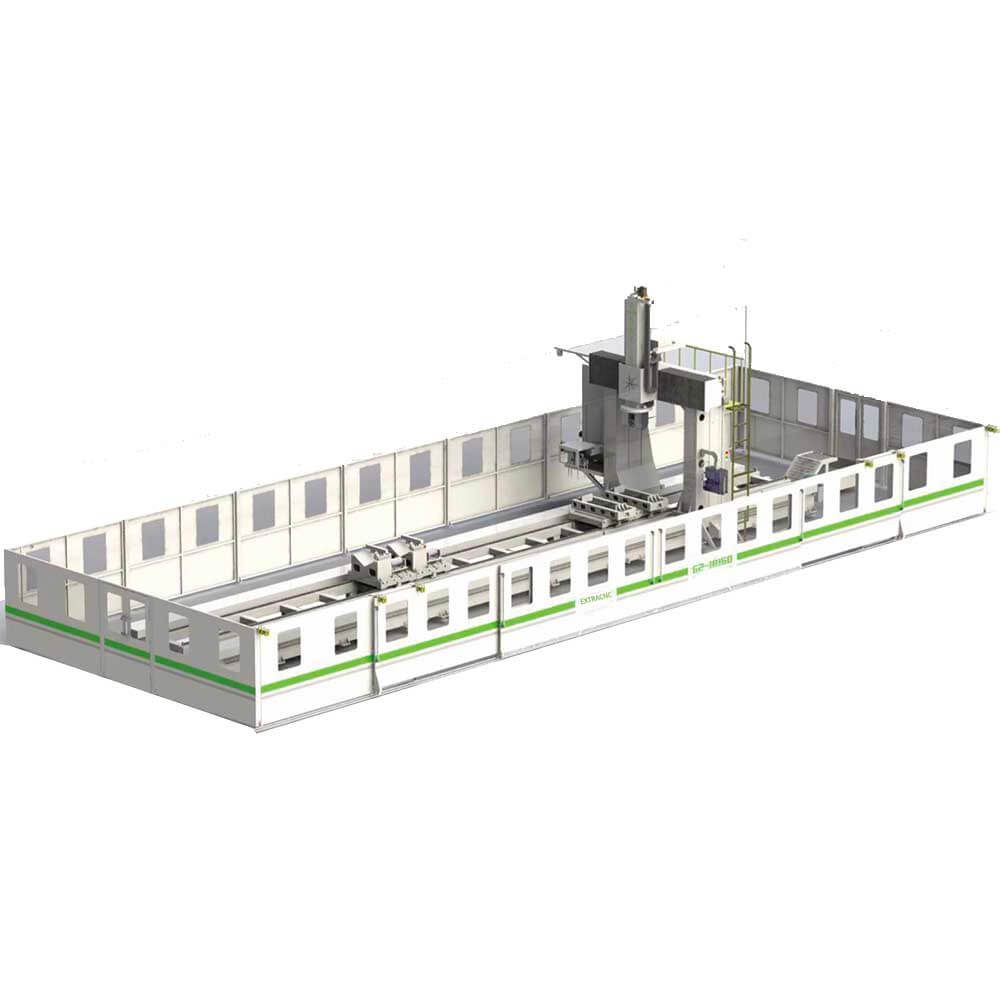

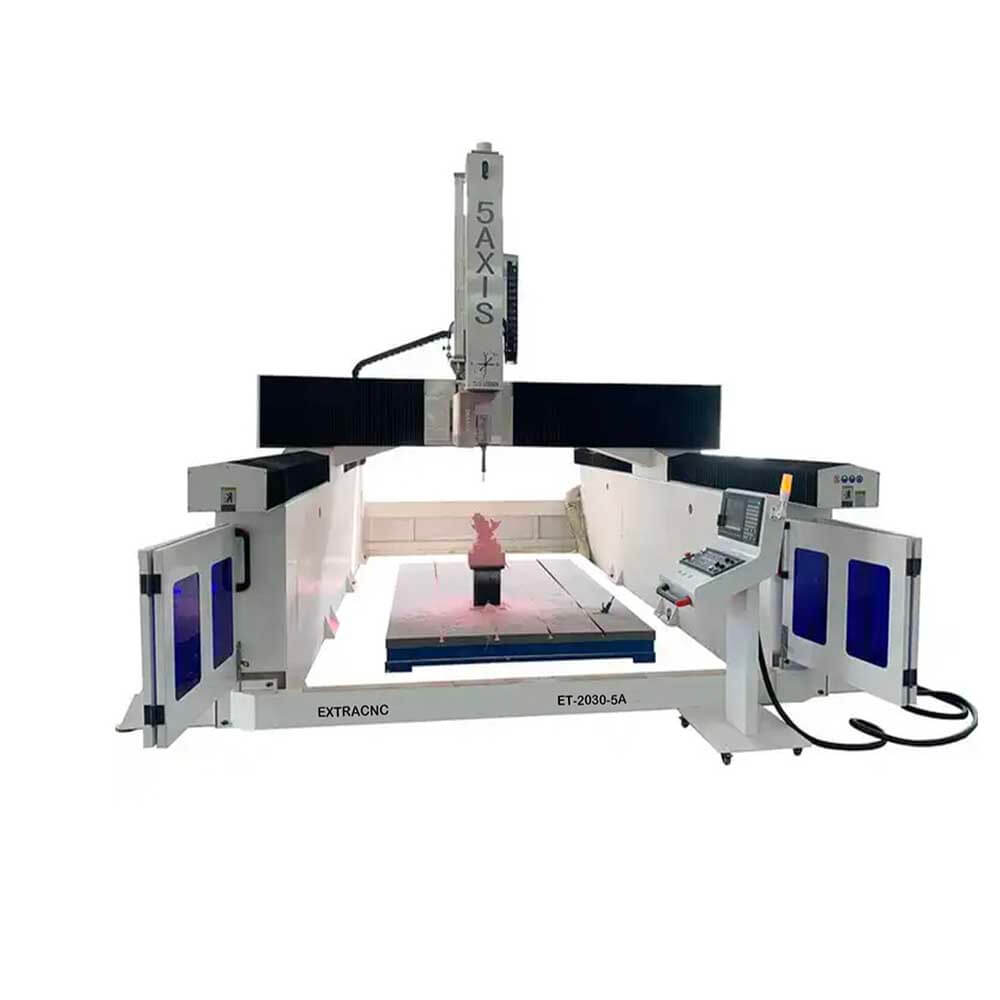

The Small 5 Axis CNC Machining Center is a compact, high-precision solution for 3D CNC modeling. Designed for versatility, it allows for simultaneous movement across five axes, enabling the creation of intricate designs in a single setup. Ideal for woodworking, prototyping, and small-scale production, this machine enhances productivity and ensures high-quality results, making it an essential tool for modern manufacturing.