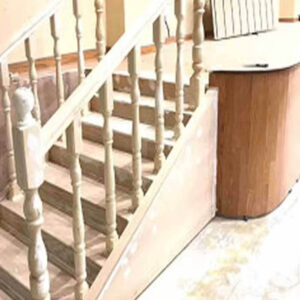

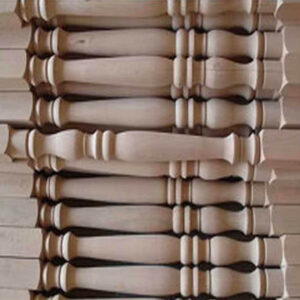

The Professional CNC Wood Turning Lathe for Roman Pillar Columns is perfect for crafting detailed furniture pieces like table legs, chair legs, and decorative elements such as stair spindles and Roman pillar columns. Ideal for both custom and high-volume production, it offers precision, efficiency, and high-quality results for woodworking professionals.