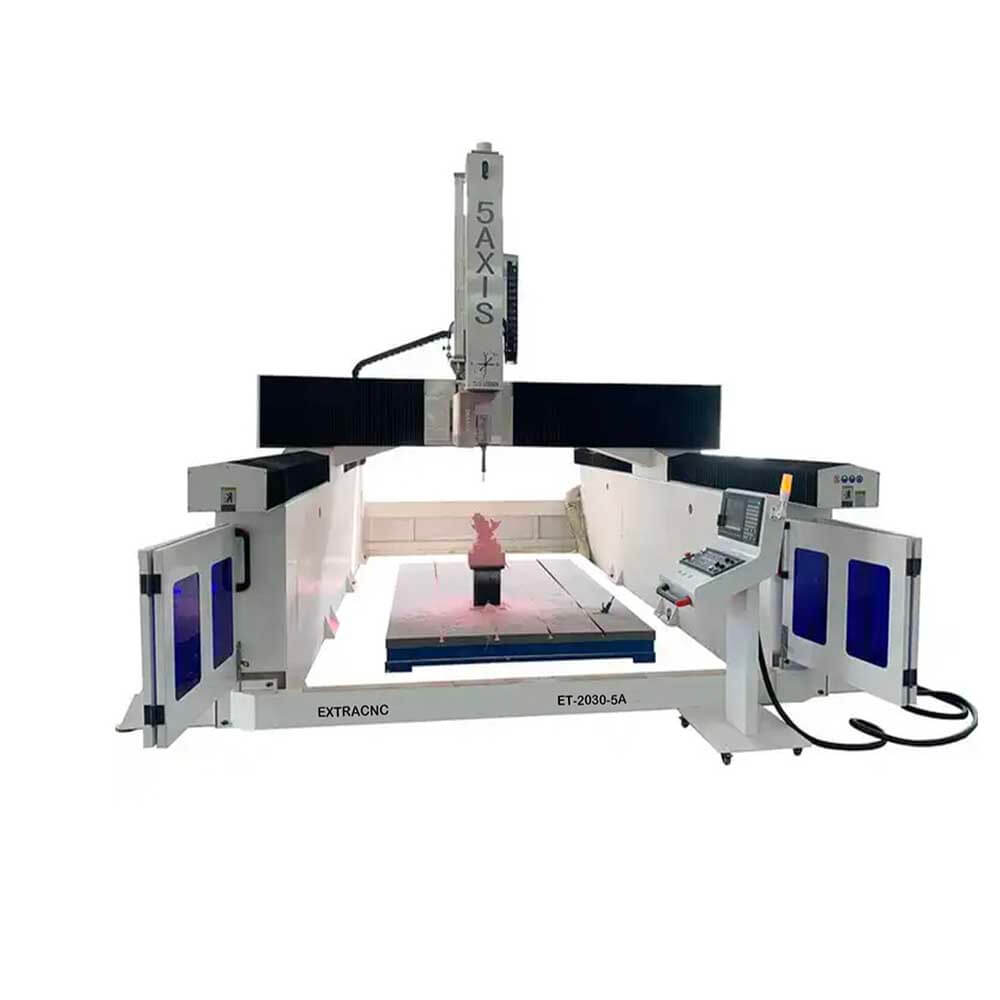

Compact Design: Optimized for small workspaces, this machining center provides powerful capabilities without occupying excessive floor space, making it ideal for workshops with limited room.

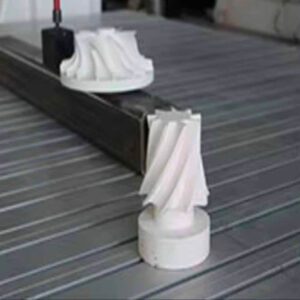

High Precision: Equipped with advanced motion control technology, it delivers exceptional accuracy and repeatability for intricate 3D modeling tasks, ensuring detailed and high-quality outputs.

5-Axis Capability: Allows for simultaneous movement along five axes (X, Y, Z, A, and C), enabling complex geometries and multi-sided machining in a single setup, which enhances productivity.

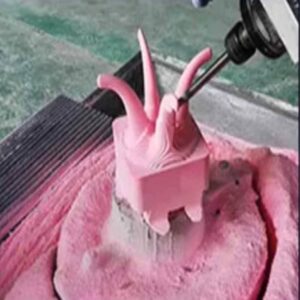

Versatile Material Compatibility: Capable of machining various materials, including wood, plastic, aluminum, and composites, providing flexibility for different projects and industries.

User-Friendly Interface: Features an intuitive control system that simplifies programming and operation, making it accessible for both experienced machinists and newcomers to CNC machining.

Robust Spindle Options: Typically includes high-speed spindles that provide superior cutting performance, allowing for efficient milling, engraving, and drilling of complex designs.

Automated Tool Changing: Often equipped with an automatic tool changer (ATC), reducing downtime between operations and increasing overall efficiency in production.

Enhanced Software Compatibility: Supports various CAM software packages, facilitating seamless integration into existing workflows and allowing users to leverage advanced programming capabilities.

Integrated Cooling System: Features a built-in cooling system to maintain optimal spindle temperature, enhancing tool life and performance during extended machining operations.

Safety Features: Designed with multiple safety mechanisms, including emergency stops and protective enclosures, ensuring a secure working environment for operators.