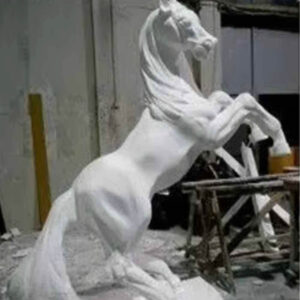

The 4-Axis CNC Foam Router is used for precision milling of foam, wood, and non-metallic materials, ideal for creating complex 3D shapes and molds in industries like automotive, aviation, and mold making. It offers high accuracy and efficiency for producing detailed prototypes and molds.