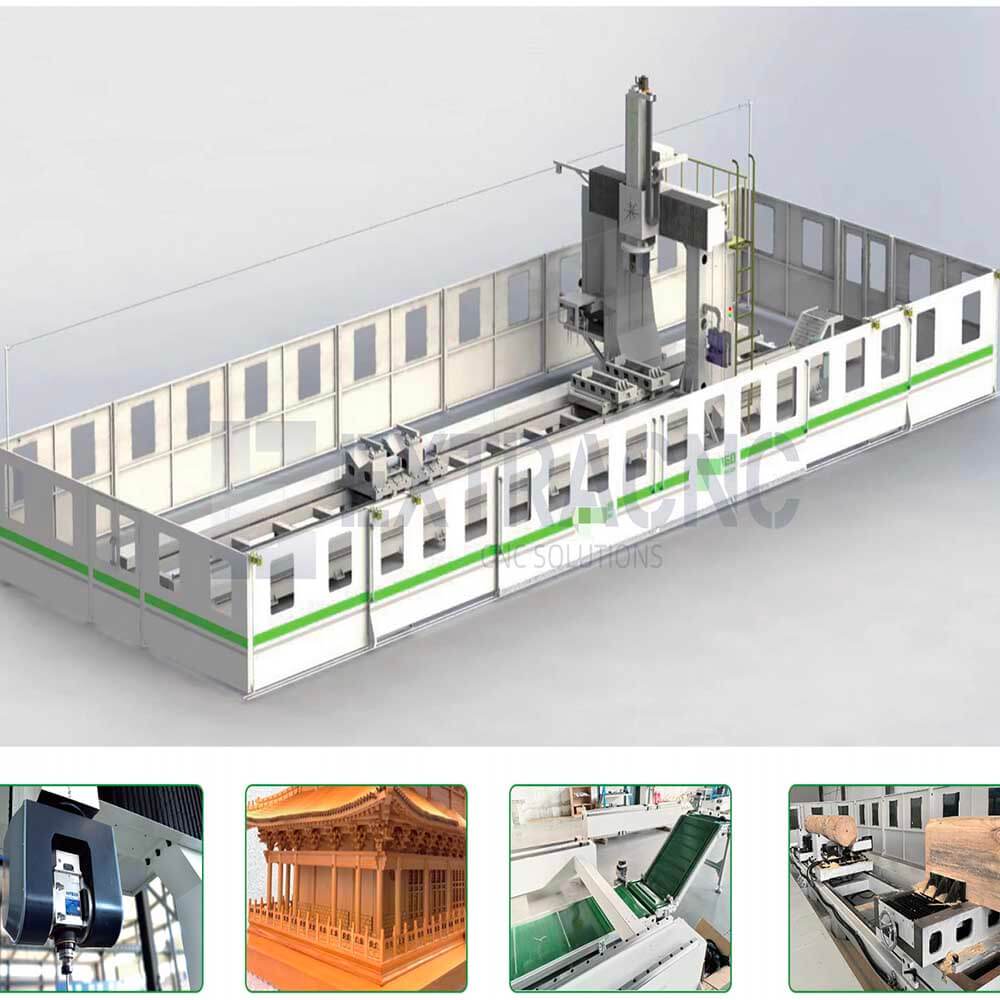

Automotive Applications: Unibody vehicle designs, interior components, luggage carriers, sunroof tracks, and bumpers.

Aerospace Applications: Molds and patterns for parts, propellers, and turbine blades.

Rail Transit Sector: Covers for motor vehicles, roof deflectors, interior furnishings, control panels, and complete restroom units.

Wind Energy Mold Applications: Blade molds and nacelle cover molds.

Foundry Applications: Wooden molds, lost-foam casting molds, composite material molds, and sand molds.

Maritime Applications: Plug molds, deck molds, hull molds, and trimming molds for fiberglass.

Composite Material Applications: GRC, GRP, FRP, ABS, EPS, plastics, clay, epoxy, and other composite substances.

Sculpture and Scene Creation: Decorations for theme parks, movie props, and humanoid sculptures.

Furniture Manufacturing: Mortise and tenon joints, solid wood curved surfaces, handrail elbows, stair turnings, and chair backs.

Bathroom Industry: Molds for bathtubs, sinks, toilets, and processing various gypsum products.

New Energy Sector: Battery enclosures for new energy technologies.

Modeling Applications: Any type of 3D shapes and real estate models.